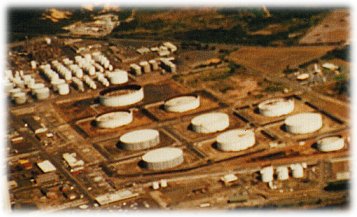

Oil Refinery |

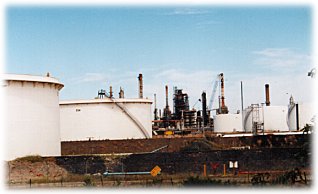

Photo: Annette Hogan |

| The Kurnell Oil Refinery is the most prominent of the Peninsula's many industrial establishments. It is one of the largest refiners of oil in Australia, producing in the vicinity of 6.5 billion litres of petroleum each year and is reported to supply two thirds of the Sydney market. It employs about 700 people. |

|

The refinery is licenced by the NSW Environment Protection Authority and this licence attempts to manage and control the many environmental impacts associated with the refinery operations including air emissions, noise emissions, emissions to water, and sludge and soil conditions on the refinery's landfarm.

The Refinery releases a range of pollutants into the air including Sulphur Dioxide.

The Refinery currently releases effluent to ocean outfalls at Yena Gap and collects and disposes of cooling water in Botany Bay. The refinery's stormwater is released into Botany Bay and during large storm events oily substances flow into the Bay often creating a minor temporary 'slick' on the surface. |

|

| Transport of oil to and from tankers is facilitated via pipes on a purpose-built wharf. |

|

There have been a number of oil spills in Botany Bay including one in 1999 which resulted from a leak in a tanker unloading at the wharf. Refinery staff undertake emergency exercises to maintain and improve preparedness for major oils spills in the Bay.

The Refinery in the late 1990s moved to implement an effluent improvement plan including the construction of a biotreater at a cost of $14 million. This is designed to reduce the impact of organic pollutants from the refinery. Bio-organisms are used to treat refinery waste water and contaminants (oils and phenols) before they are released at Yena Gap. Accumulated sludge is then sent to the landfarm. Monitoring the effectiveness of the effluent improvement measures at Yena Gap is to be undertaken by an independent expert.

The Refinery's Environmental Management Plan process is a further measure designed to improve the Refinery's environmental performance and includes details on Licence Compliance, Environmental Management Systems, Waste Water Treatment and Control, Waste Management, Soil and Groundwater, Air/Noise emissions and Marine Oil Spill Preparedness.

The noise from the refinery is licenced not to exceed 70 decibels measured one metre from the plant boundary. Noise from the refinery is, none-the-less, audible from most of Kurnell including from the National Park.

Much of the monitoring required by the EPA licence is undertaken internally by the refinery. Any breaches of the licence must be reported to the EPA and records kept for at least 3 years. In late 2000, concerns were raised over the extent of odours detected outside the refinery's boundaries. In response, environment groups and residents called on the EPA to establish a new air quality monitoring station in Kurnell.

There have been many conflicting reports and rumours regarding the long term future of the refinery operations on the Kurnell Peninsula. Much of this has been focussed on a possible greater emphasis on imported fuel which is cheaper than locally refined product.

The Federal Government in the late 1990s introduced a cleaner fuels policy which also has implications for the future of the refinery. In order to meet the requirements of the new policy, Caltex must invest $150-200 million in the Kurnell refinery by 2006 or the refinery may close. Some efficiency improvements at Kurnell have been achieved but reportedly, more needs to be done.

Indeed, the Refinery is beginning to show its age. In late 2000 a partial shut down of the refinery was necessary to allow the demolition of an exhaust stack that had developed a structural flaw.

There have been a number of accidents in the Refinery in recent times along with an ongoing industrial dispute over pay and conditions. |

| top of page |